Three Cut Outs - Three Days

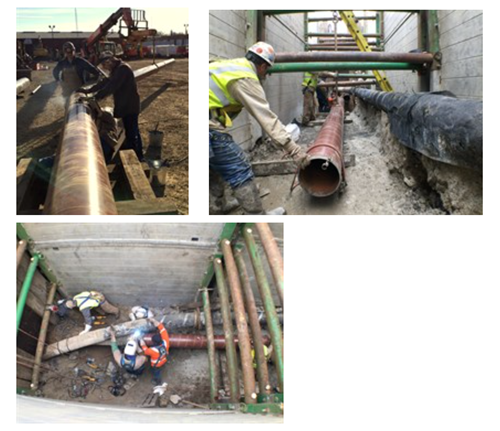

A recent project awarded to Midwestern Contractors (MWC), involved the removal of temporary Black Diamond repairs to three bends where external corrosion was discovered. Our customer wanted permanent repairs to these three bends. To effect these repairs MWC mobilized crews to excavate all three bends. One bend required shoring boxes eighteen feet deep and over 60 feet long. Two pipes were running parallel to each other with one crossing over the top of the section to be cut out. This posed challenges in actually removing the defective section. The other two cut outs were straightforward and required very little shoring.

After the pipes were exposed our fitters made measurements of the length, degree of bend and degrees of roll. With these measurements they set up in our fabrication yard and cut segmentable fittings to length, beveled pipe, welded the assemblies and end caps and hydrotested everything for all three cutouts.

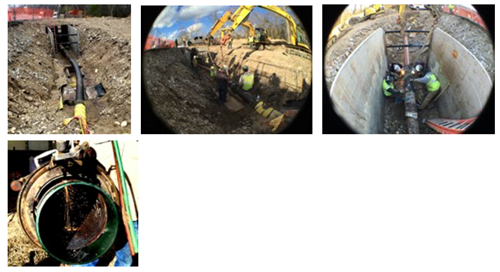

The line would be purged and blown down and we would have three days to tie in all sections. Each assembly was trucked to the cutout site and the crews started final fitting and welding moving from North to South. The project went as planned, each piece was fitted in place, tacked and welded. All welds passed X-ray and the job was completed on schedule.

Safety protocols were in place to deal with slip and trip hazards, high voltage overhead power lines, and traffic control along highways. The entire crew demonstrated a high degree of safety awareness and completed the projects with no incidents or injuries. Thanks goes to our Project Managers, Foreman, Crew and Fitter/Welders for doing a good job in a tight schedule.

Final photos show completed tie in at first cutout. A piece of segmentable fitting being welded in place and the third cut out site. Credit to Ztylus for the 4-in-1 lens kit used to take these photos.